QC Profile

Introduction:

Retractable awnings are popular outdoor shading solutions that provide comfort and protection from the sun and rain. To ensure customer satisfaction and the longevity of these products, it is crucial to have effective quality control measures in place during their production. This article will outline key aspects of quality control for retractable awnings, including materials, manufacturing processes, and testing procedures.

-

Materials:

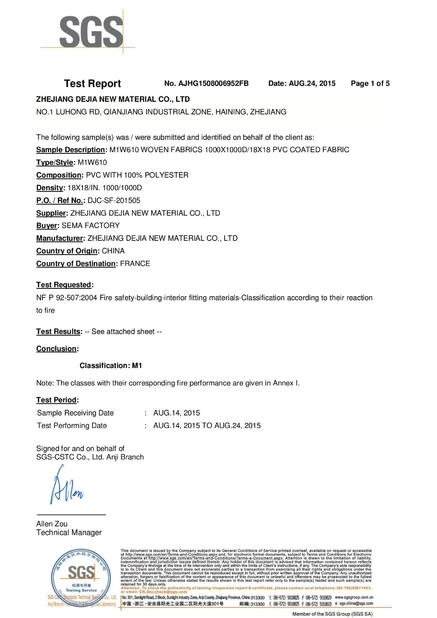

The quality of materials used in retractable awnings significantly impacts their performance and durability. Quality control should involve rigorous checks on the fabric, frame components, and other crucial elements. The fabric should be made from robust, weather-resistant materials such as acrylic or polyester, ensuring resistance to fading, tearing, and UV degradation. The frame components, including the arms, brackets, and mechanisms, should be constructed from sturdy materials like aluminum or stainless steel to guarantee structural integrity and longevity. -

Manufacturing Processes:

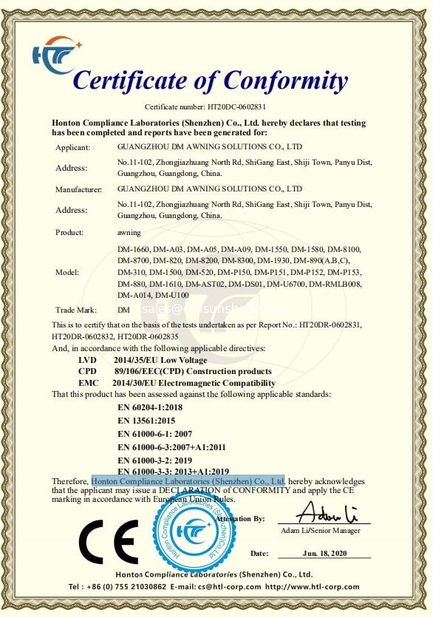

Stringent quality control measures must be implemented throughout the manufacturing processes of retractable awnings. Regular inspections and audits should be conducted to ensure compliance with industry standards and regulations. Attention to detail during assembly, including proper alignment of components, secure fastening, and smooth operation of the retractable mechanism, is vital. Adequate training should be provided to workers, and quality control checkpoints should be established to identify and rectify any defects or deviations from specifications. -

Testing Procedures:

Comprehensive testing procedures are essential to verify the functionality and reliability of retractable awnings before they are released to the market. This includes both in-process and final product testing. In-process testing involves checks at various stages of manufacturing to identify any issues early in the production cycle. Final product testing should encompass assessments such as wind resistance, water resistance, and overall structural stability. These tests should be conducted in accordance with established standards to ensure that the awnings can withstand various environmental conditions and meet customer expectations. -

Quality Assurance:

Implementing a robust quality assurance system is crucial for maintaining consistent quality standards. This involves documenting and monitoring all quality control activities, including inspections, tests, and corrective actions taken. Regular audits should be conducted to assess adherence to quality control protocols and identify areas for improvement. Feedback from customers and market research should also be collected to address any quality concerns and drive continuous improvement efforts.

Conclusion:

Effective quality control is vital for ensuring the quality, reliability, and longevity of retractable awnings. By implementing stringent measures related to materials, manufacturing processes, testing procedures, and quality assurance, manufacturers can produce awnings that meet or exceed customer expectations. Continuous monitoring, evaluation, and improvement of quality control practices will contribute to the overall success and reputation of retractable awning products in the market.